Design and development of machines

Design, engineering & development

The successful production of single-purpose machines to order presupposes a strong background, especially in the field of development, design and engineering. We have been following this path since the beginning. Within our company, several separate departments and teams are working on the development of your new technology, which complement each other and carry out inspections.

Construction office

Part of the company ROBEX DK, s.r.o. has been a design office since 2006. The task of the designers is to find the optimal technical solution according to the needs of our customers and then to process the technical documentation in 2D and 3D for our own production. The basis is a request from the customer. Simply put, what the machine should do, ideally how it should do it and how much the frame price should be. designers are then looking for a solution to prepare just such a unit for production. The entire work of the designer is divided into several sub-phases.

Thanks to our own design office, we can provide a wide range of services. From the initial design of the concept, subsequent development using SolidWorks to the final production of technical and production documentation, complete production, delivery, training, warranty and post-warranty service.

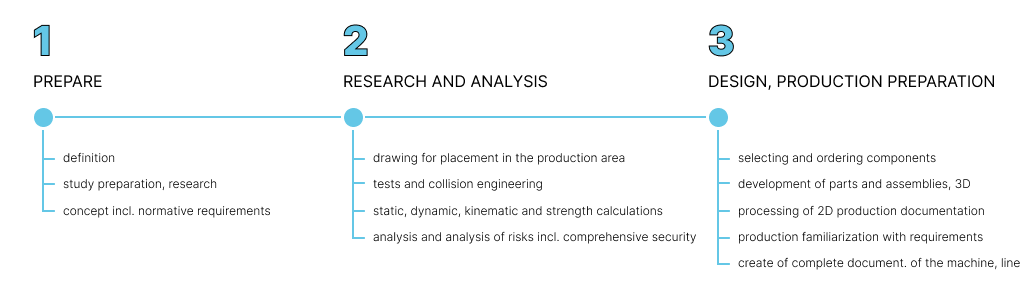

Stages of development

The first stage of development is the preparation of studies. They also include test results of the material you are processing, detailed solutions and subsequent optimization with regard to price, production possibilities, etc.

As part of the complete development of the product, the entire machine or line, it is necessary to prepare a conceptual solution based on the study. In addition to classic construction work, we also provide other independent development and research work.

After the customer approves the concept and the actual start of the order comes the classic design activity, namely the development and creation of documents for parts, assemblies and subsequent 3D models. Our design office uses SolidWorks software for designing 3D models, whose parametric processing allows us to respond flexibly to any changes in the project specifications. The resulting technical documentation meets technical standards and thus guarantees possible broad and simple applicability to our customers.

As part of project preparation, the customer's premises and requirements are always taken into account. Of course, we also pay attention to the safety and faultless usability of the proposed parts, machines or lines. That is why, when processing projects, we do not forget to check the conflicting states of the chosen principle.

We subject each part of the machine or line to special checks and carry out strength analyzes and calculations not only of entire sets, but also of individual components in terms of deformation of parts due to load or deformation of parts due to heat. Based on the calculation, we will determine the critical points, the most exposed parts, the maximum deformations, etc. The strength analysis also includes the design of the necessary modifications and the subsequent optimization of the structure. A similar process is the processing of risk analysis and analysis, where we identify all risks and propose adjustments to eliminate serious risks. Residual risks are eliminated by some of the effective measures.

The agreed and checked development phase goes into 2D form and is ready for production. In parallel, components and elements for the machine or line are selected and ordered.

Acquainting production with the specific requirements for assembling the machine and its individual parts is a necessary part of development when handing over to production. In most cases, the presence and control of the designated designer during the actual assembly in production is also necessary.

After the assembly and completion of the machine, the construction proceeds to the completion and control of drawing documentation and the creation of complete documentation. These are not only production drawings, but also service manuals, a list of replaceable parts and their availability, a user manual or operating instructions. The construction is also involved in trials and tests.

Design and simulation environment

We use SolidWorks in the optimal version and scope just for drawing single-purpose machines and lines with their indisputable specifics. SolidWorks, as one of the world's most used design software, brings us the efficiency of processes in all phases of the development of the whole.

SolidWorks offers us powerful volumetric and surface modeling, vertical tools for sheet metal parts, weldments and molds, work with unlimited extensive assemblies and automatic generation of production drawings. We save your time and thus your money.

The use of some parts of the documentation for another job significantly increases the flexibility in the design. In addition, everything is multi-directionally backed up, increasing the repeatability of elements.

And what about the construction?

Our independent design office is at a top level, not only in terms of hardware and software equipment, but also in terms of experience with machine development.

We try to make the most modern technologies available to Czech companies as well. Our design office has already implemented various projects, among which, for example, the development and construction of recycling technology for connection of foam materials, connection of various materials, giant rewinding lines, automatic laying tables, melting technology, copying and CNC machines, measuring machines, sealing and profiling lines, various cutting and cutting workstations, vertical and horizontal saws, piece counters and many others.

As part of the expansion and utilization of our company's production capacities, our design office also participated in the development of the hot-melt cutting technology for polystyrene and insulation CleexCut (you can find more here).

In addition to standard design and development work, we also provide technical proposals in engineering, automotive, energy and development of control systems.

The machines manufactured by us are always designed to minimize possible future maintenance. Even so, however, mechanical wear must be taken into account and it is therefore necessary to carry out regular machine maintenance. That is why we have included service activities and trained qualified service personnel. Find out about the possibilities of cooperation on the service and maintenance of machines HERE!

Other services such as: regular service, keeping spare parts in stock, overhaul of your older machines, etc. can also be arranged individually.

Each machine is always made to measure. It is therefore important to know all your needs and future requirements. Our presentation only outlines the overview of machines manufactured and delivered by us, in case you have not found any suitable machine or principle, please contact us. We will offer you other possible solutions.

- custom production of single-purpose machines according to our design (of course you will receive a simple offer free of charge after specifying the specification)

- the possibility of supplying separate drawing documentation for the machine, the possibility of cooperative cooperation

- the possibility of production according to the documentation provided by you

- design and implementation of modifications to existing machines and lines

Electrical department

Electroprojection

Our electrical department is ready to deploy both long-proven solutions and solutions related to new technologies.

The main currency is the close mutual cooperation of electroprojection with other departments of our company, especially with the design team, production and sales. Last but not least, also directly with the customer. Within the electrical department, we also cooperate with other companies in the field and, last but not least, with the technicians of supplier components. This collaboration has already resulted in a lot of new ideas and solutions that boldly stand up to the competition.

Our employees consistently pay attention to their expertise. Individual workers participate in regular trainings, seminars, incl. passing the relevant exams.

Electrical project documentation is usually processed in the latest versions of the ProfiCAD design software.

On request, we are able to process the schematic in E-plan or SolidWorks Electrical. With ProfiCAD, it is possible to install a free version for simple modifications in case of future changes, which we see as an advantage for customers.

Elektro - instalace, kompletace, servis a opravy

The high technical level of our technicians, both in small projects and in large and complex technological units. These can be projects of mass-produced devices, prototypes of unique machines, complex lines consisting of several separate units or interconnected lines controlled from the control room, machines with data collection as well as the repair of historical machines, especially for the textile, paper and automotive industries. Everywhere, thanks to many years of experience and purposeful work on knowledge, our electricians will meet even the most demanding requirements.

Thus, our employees participate in dozens of events of a diverse nature, from small electrical installations, through machine control systems, HVAC equipment and production lines to complete production documentation of technological units.

Control systems and programming

We offer comprehensive services in the field of control systems, from design, through programming, to installation and commissioning. Programming and visualization using HMi or PC using all standards are a matter of course. If necessary, we are able to tailor graphics and controls according to the customer's standards.

Thanks to the long history of our company, we have considerable software and hardware equipment for modifications, reprogramming and identification of defects even on old control systems, PLC, HMI, but also drivers, servo drivers, frequency converters and sensors of many brands (Omron, Hitachi, Lenze, Bosch Rexroth, Schneider, Siemens, Unitronics, Xinje, X-logic, Kinco, ReeR, Yaskawa and many others).

And why ROBEX DK, s.r.o.?

The basis for us is to create a quality proposal and to realize the entire project in the shortest possible time and at an appropriate price. Our experienced team of technicians and designers is here for you. We carry out development and construction work in the field of textile and processing industry, automotive, electrical engineering, engineering and general automation.

Our practices and experience are constantly evolving and improving, but the foundation remains the same:

- a human approach with a clearly defined code of ethics

- high-quality and efficient design of the machine or fixture

- use of highly durable and high-quality components

- emphasis on ergonomics of use and safety

- maximum flexibility to customer wishes

- the art of moving in the corporate environment of large multinational customers

- quick response and permanent team of experienced technicians

- it does not end with handing over the work for us - service & spare parts